Oil Skimmers – Effective and simple

Oil skimmers are an excellent tool in the war against petroleum basked spills as all knows that oil and water is a big mess that is usually very hard to clean up especially when the quantity of oil spilled in large.

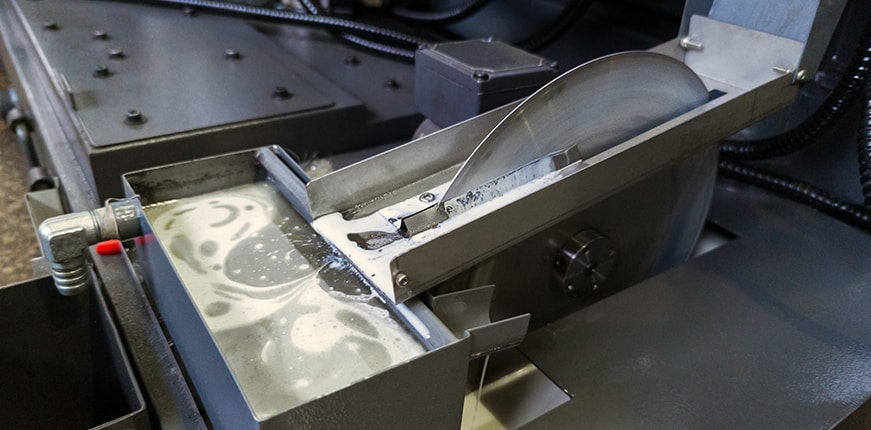

The most effective, although slow way of getting oil off the top pf water is by using oil skimmers. They work by using the adhesive nature of the oil to their benefit. Oil might cling to any surface that it comes into contact with, so these plants offer a never ending surface for the spilled petroleum product to cling, to clean that surface and they continuously repeat the process.

Since the process is regular and you don’t have to replace chemicals or removed soiled items, a large number of spilled products can be removed in a short time span.

Oil skimmers work well in a cleaning up oil and petroleum-based products on water after major spill events, but for many they are used as a maintenance item to remove small petroleum sheens from the surface of retention ponds and tanks at manufacturing facilities that use petroleum-based products in the manufacturing operations.

Oil skimmers are very simple devices that can-do excellent job when they are crafted to do. Like any other piece of machinery, its absolutely critical that the right size is chosen based on the areas that requires to be cleaned. The manufacturers of these can offer guidance and direction as to what the reasonable capacity each of the models can realistically offer.

As of these simplistic natures, oil skimmers are very easy to repair, clean and maintain. Any person that is skilled in equipment maintenance will never have issue adjusting and maintaining the majority of the units that are available on the market.